With technology to the point that sets new standards in terms of precision and efficiency in injection molding, we want to share our perspective of the future in plastics processing. Discover how our intelligent, automated production solutions – including complete cell setups and peripherals – can seamlessly integrate into your operations and drive productivity for you.

Live, at booth A1-1103

Fakuma at a Glance

- October 15 – 19, 2024

- Opening hours from 09:00 – 17:00 (Saturday – 15:00)

- Topics: Digitalization, automation, flexibility, energy efficiency – and sustainability

- Haitian in Hall A1-1103

Smart , Flexible, Solutions

Haitian at Fakuma

- Latest machine technology with live applications

- 3 exhibits on Haitian booth – 3 exhibits on partner booths

- Complete production cell made by Haitian

- German premier of Haitian peripheral devices

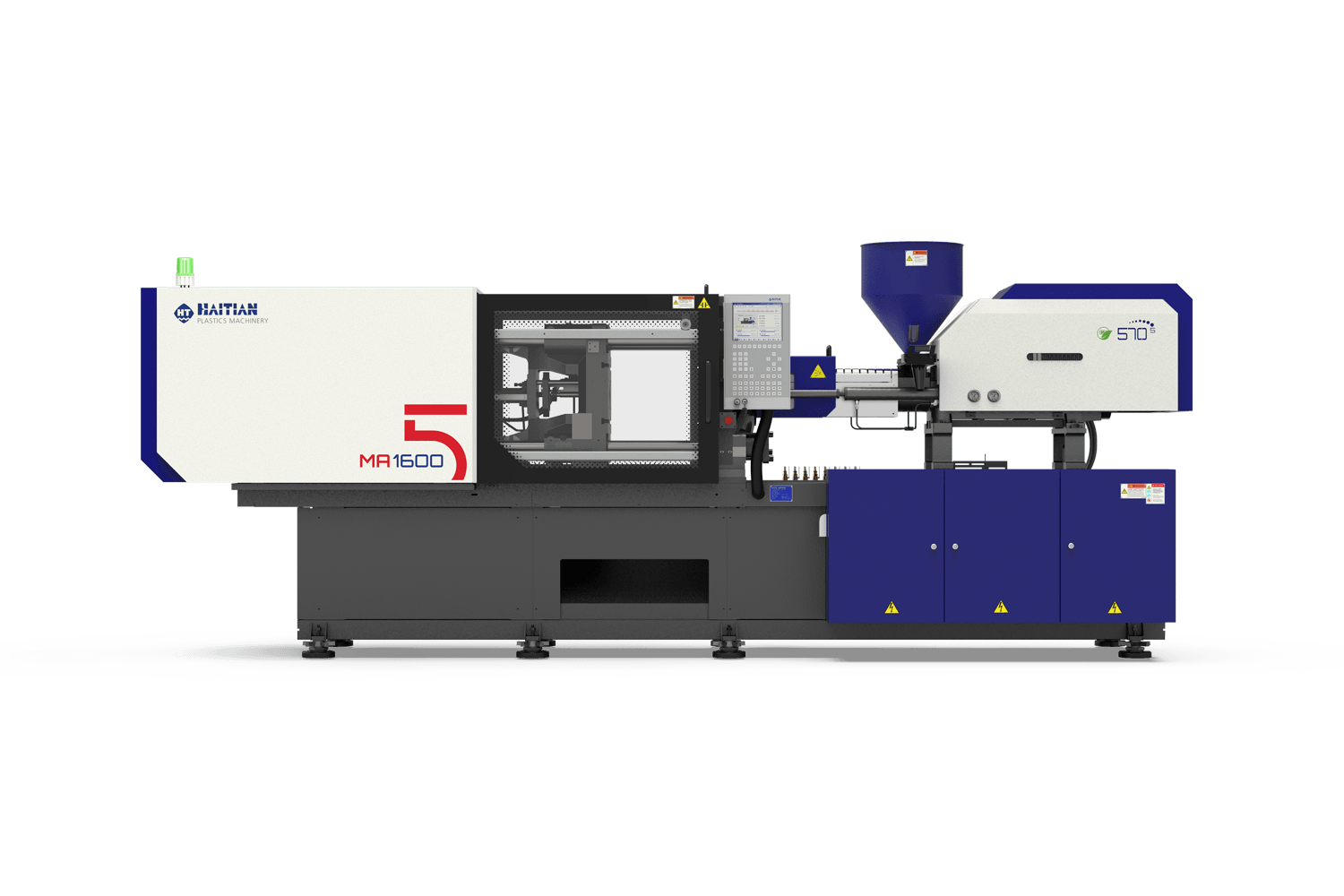

The Generation 5

- 20-40% energy saving with electrical charging as standard (servo-hydraulic IMM)

- Improved plasticizing components and durability

- Smart HT·XTEND machine features as standard

- High-response servo drive with fast, dynamic custom power system

- New UI large-screen panel and powerful control

The Generation 5

- 20-40% energy saving with electrical charging as standard (servo-hydraulic IMM)

- Improved plasticizing components and durability

- Smart HT·XTEND machine features as standard

- High-response servo drive with fast, dynamic custom power system

- New UI large-screen panel and powerful control

Find us on our partners booths

Get your free Fakuma Ticket

… or use this direkt Link for registration

Schedule a meeting

Get in touch with your sales- or service representative.

We are looking forward meeting you at Fakuma.