HT·XTEND stands for the digital transformation of the new series at Haitian International. Our 5th machine generation combines hardware with digital intelligence for self-optimizing production. The fact that the software is developed and programmed entirely in-house not only gives Haitian flexibility and independence, but also ensures that maximum cost efficiency and quality are achieved. The majority of HT·XTEND functions are available in the standard configuration and can be operated without training, delivering immediately visible results.

In brief: HT·Inject – constant part weight

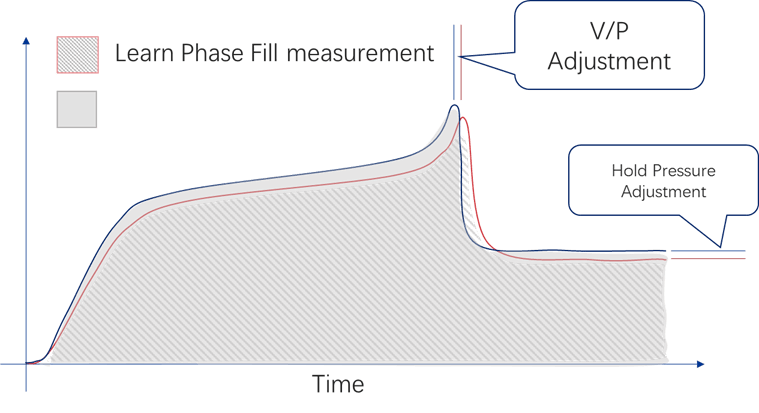

HT·Inject ensures a constant shot weight and thus consistent quality of the injection-molded parts by intelligently monitoring and real-time adjustment of the injection process. With the help of a self-learning algorithm, the system compensates for external influences such as ambient temperature, humidity, etc. and changes in the viscosity of the plastic by dynamically adjusting the injection volume and holding pressure. The adjustment takes only a few cycles.

HT·Inject is included in the standard package and can be easily integrated into existing production processes without the need for additional training.

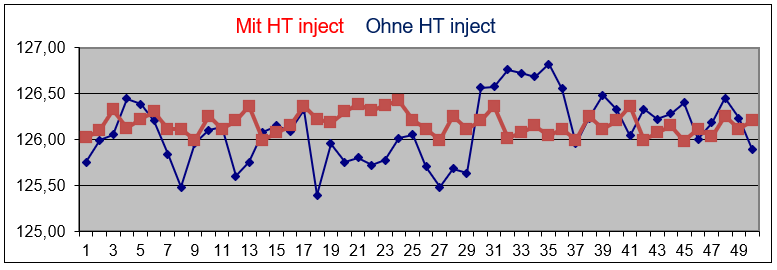

Live at Fakuma: A series of tests with the 5th generation of the MA2000V using HT·Inject and recyclate PP achieves impressive results: the weight tolerance of the molded parts is reduced from 1.4 % to 0.49 %.

We look forward to your visit in Hall A1 / 1103.